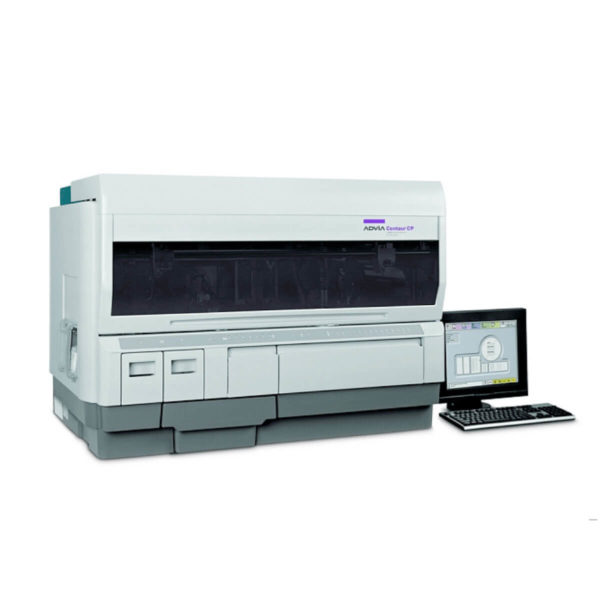

Siemens Advia Centaur XPT Immunoassay System

In Stock

Product Code: SCXPT001

Manufacturer: Siemens Healthineers

Meet your sales rep Lee Doughton, for the West USA region.

Would you like to schedule a 30-minute consultation with Lee Doughton?

Yes, Schedule a callDesigned with one of the most advanced software packages on the market, the ADVIA Centaur® XPT System is among the highest-throughput systems available. The ADVIA Centaur XPT System delivers the results that clinicians depend upon for accurate diagnoses and better patient care—and does so predictably and consistently.

Siemens unites innovative workflow solutions with clinical excellence in the ADVIA Centaur XPT System, leading to greater laboratory productivity to stay ahead of increasing workload demands.

- Simplified operation enhances lab efficiency.

- Cutting-edge immunoassay testing supports clinicians in the screening, diagnosis, and monitoring of the most complex diseases.

- Powerful automation and software streamline and accelerate your workflow.

Features & Benefits

Simplified, continuous operation

- Intuitive, icon-driven user interface for simplified training and operation

- On-the-fly loading and unloading of samples, reagents, and supplies

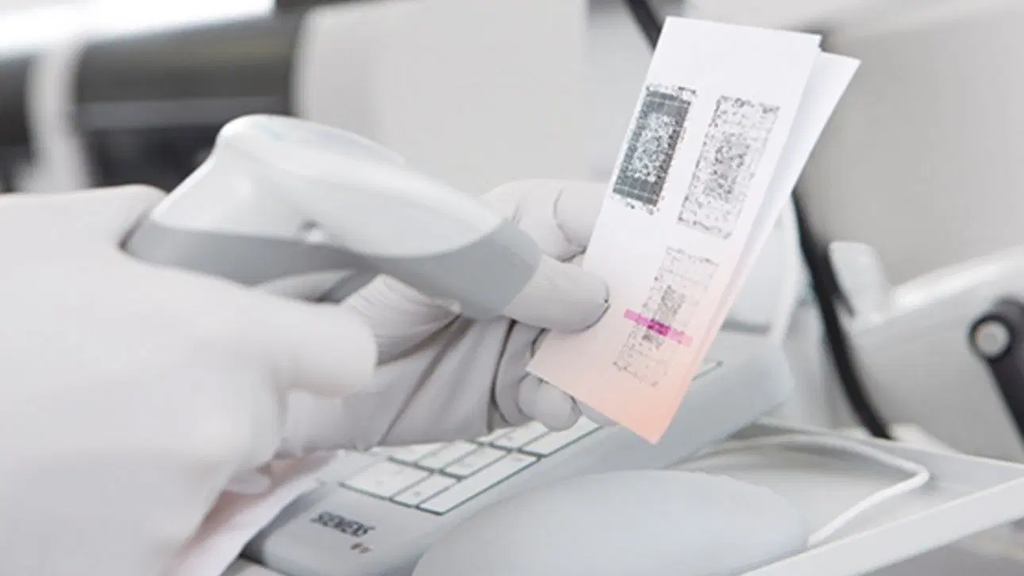

- 2D bar-code scanner uploads test definitions with one easy scan, saving valuable time

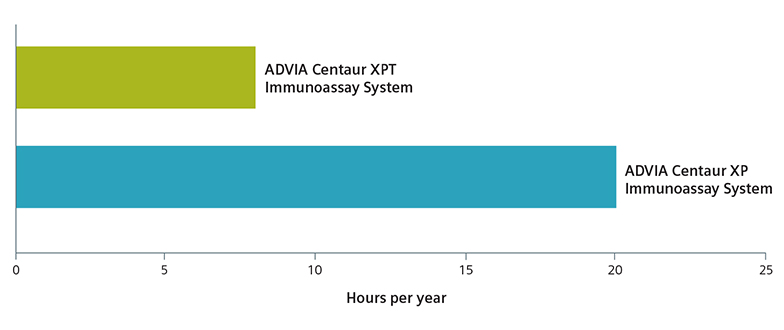

- Automated daily maintenance and no monthly cleaning procedures

- No daily startup procedure

- Status light displays system alerts visible from anywhere in the laboratory

Accurate, timely results

- Comprehensive menu supports over 70 tests*

- Versatile, advanced AE technology, with over 40 active patents, enables continual introduction of new and innovative assays

- Up to 240 tests per hour for fast turnaround, even during peak workload times

- STAT port allows priority sampling at any time, even when connected to automation

- Highly stable, ready-to-use reagents are used on all ADVIA Centaur systems

- Disposable sample tips ensure no sample-to-sample carryover

- Automated clot management virtually eliminates operator intervention

- SMART algorithm software automates repeat and confirmatory testing of reactive samples

Powerful, seamless connectivity

- Designed for automation; requires no additional robotics

- Point-in-space technology enables direct-from-track sampling

- STAT samples can be front-loaded at any time for immediate sampling, driving rapid turnaround time (TAT)

- Direct connectivity to Siemens Automation Solutions, the CentraLink™ Data Management System, and Siemens Remote Service (SRS) , enabling laboratories to adapt and grow as their workloads demand

Anemia

Active B12

Ferritin

Folate

RBC Folate

Vitamin B12

Autoimmune

Anti-CCP

Bone Metabolism

Intact PTH

Vitamin D Total

Cardiac

BNP

CKMB

High-Sensitivity Troponin I (TNIH)

Myoglobin

TnI-Ultra™

Diabetes

C-Peptide

Insulin

Liver Disease – NASH

ELF™ [Enhanced Liver Fibrosis]

Hepatitis

Anti-HBs2

HAV IgM

HAV Total

HBc IgM

HBc Total

HBe Ag

HBs Ag Confirmatory

HBs AgII

HCV***

HIV

HIV 1/O/2 Enhanced (EHIV)§

HIV Combo§

Immunosuppressant Drugs

Cyclosporine

Everolimus**

Tacrolimus**

Inflammation

IgE, Total

Metabolic

Cortisol

Homocysteine

Oncology

AFP

BR 27.29

CA 125II‡

CA 15-3

CA 19-9

Calcitonin

CEA

Complexed PSA

PSA

Serum HER-2/neu

Reproductive Endocrinology

AFP

Anti-Müllerian Hormone**

DHEAS

Enhanced Estradiol

Free βhCG‡‡

FSH

hCG

LH

PAPP-A‡‡

PlGF**

Progesterone

Prolactin

sFLT-1**

SHBG

Testosterone II

Special ID

EBV-EBNA IgG**

EBV-VCA IgG**

EBV-VCA IgM**

Syphilis

Zika IgM††

Therapeutic Drug Monitoring (TDM)

Carbamazepine

Digitoxin

Digoxin

Gentamicin

Phenobarbital

Phenytoin

Theophylline

Valproic Acid

Vancomycin

Thyroid

Anti-TG

Anti-TPO

Free T3

Free T4

T Uptake

Total T3

Total T4

TSH3-Ultra

TSH

ToRCH

CMV IgG

CMV IgM**

Herpes-1 IgG

Herpes-2 IgG

Rubella IgG

Rubella IgM

Toxoplasma IgG

Toxoplasma IgM

Technical Specifications

| Product Specifications | |

|---|---|

| System Description | Random-access immunoassay system |

| Test Throughput | Up to 240 tests per hour |

| Time to First Result | 18 minutes; results every 15 seconds thereafter, assay dependent |

| Assays Onboard | 30 assays |

| Disease-State Assay Groups | Allergy, Anemia/Iron Metabolism, Bone Metabolism, Cardiac, Diabetes, Hepatitis, Immunosuppressant Drugs, Metabolic, Oncology, Reproductive Endocrinology, Special ID, Therapeutic Drug Monitoring (TDM), Thyroid, ToRCH |

| Continuous Operation | Loading/unloading of samples and consumables at any time without interrupting system operation. Includes sample racks, STATs, reagent packs, ancillary reagent packs, reaction cuvettes, sample pipette tips, calibrators, controls, wash fluids, water, and waste. |

| Sample Handling | |

| Sample Tubes | 3 mL, 5 mL, 7 mL, and 10 mL tubes; 1 mL and 2 mL sample cups; microcontainer tubes |

| Sample Input | Universal 5-position rack holds multiple tube types; 180 samples fully loaded; no-pause loading and unloading |

| Validated Sample Types | Serum, plasma, urine (assay-dependent) |

| Sample Volume per Test | 10–200 μL, assay-dependent |

| Sample Integrity Control | Pressure transducer technology with clot detection, flagging, and management; short-sample detection |

| STAT Handling | Dedicated STAT port accepts samples any time; STAT samples are processed with priority |

| Auto-repeat | User-definable |

| Sample Dilution | Automatic dilution varies by assay, up to 1:2500 |

| Auto-reflex Testing | Automatic ability to perform additional tests based on results of first test |

| Sample Pipette Tips | 840 disposable sample tip capacity |

| Sample Carryover Prevention | Disposable pipette tips ensure zero sample carryover |

| Bar Codes | |

| Sample Bar Codes | Up to 20 digits; Interleaved 2 of 5; Code 39, Code 128, Codabar; A, B, and special characters (.-+/*$%) |

| Reaction Area | |

| Reaction Cuvettes | Capacity of 1000 optical-grade plastic cuvettes |

| Reaction Bath | Air bath, 37°C |

| Assay Result Calculations | SMART algorithm software repeats and confirms reactive testing; results available as completed |

| Assay Technology | Chemiluminescence using Advanced Acridinium Ester |

| Reagent Handling | |

| Reagent Tray | 30-position reagent tray refrigerated between 4 and 10°C (39–50°F) |

| Reagent Capacity Onboard | 30 assays |

| Reagent Containers | ADVIA Centaur® ReadyPack® (various pack sizes available) |

| Reagent Integrity Control | Bar-code reagent identification, automatic inventory tracking and flagging, calibration valid tracking and flagging, reagent onboard stability tracking and flagging, reagent expired/reagent low flagging |

| Onboard Stability | 28 days (average) |

| Reagent Mixing | ADVIA Centaur ReadyPacks automatically rocked onboard |

| Ancillary Reagents | 25-position ancillary reagent tray cooled 4–8°C (39–46°F) |

| Calibration/QC | |

| Auto-calibration/Auto-QC | Available automatic QC ordering by test, control, date, and time |

| QC Data | Advanced QC package includes Levey-Jennings plots and Westgard rules |

| User Interface/Data Management | |

| Monitor | 22-inch diagonal high-resolution LCD touchscreen with adjustable height |

| Operating System | Microsoft® Windows® 7 |

| System Documentation | Operator manual, quickstart guide, and context-sensitive online help |

| Data Storage | 1,000,000 test/QC results; 500,000 can be historical; can archive to removable media |

| Onboard Maintenance Logs | Yes |

| Host Interface | RS232C bidirectional and host query; Ethernet connection available |

| Host Query | Yes |

| Remote Access & Service | 1000Base-T Ethernet port for remote access and modem for Siemens Remote Service |

| Removable Media | |

| Removable Media | CD, DVD, or USB |

| General Specifications | |

| Power Requirements | 200-240 V at 50/60 Hz; 1.2 kW maximum |

| Maximum Water Consumption | 2.5 liters (0.6 gallons) per hour |

| Drain Requirements | Minimum of 2.5 liters (0.6 gallons) per hour |

| Dimensions | With monitor: 167 (h) x 196 (w) x 104 (d) cm; 66 (h) x 77 (w) x 41 (d) in. Without monitor: 133 (h) x 196 (w) x 104 (d) cm; 52 (h) x 77 (w) x 41 (d) in. |

| Weight | 585 kg (1289 lb) |

| Compliance | Complies with international environmental, health, and safety standards |

| Noise Emission | 65 dB maximum |

| Processing Heat Output | 5100 BTU/hour |

| Ambient Temperature | 18–30°C (64–86°F) |

| Ambient Humidity | 20–80% noncondensing |

| Floor Load-Bearing Requirement | 412 kg/m2 (84 lb/ft2) |