Dynex Automated ELISA Systems

In Stock

Product Code: DXAG001

Manufacturer: Dynex

Meet your sales rep Lee Doughton, for the West USA region.

Would you like to schedule a 30-minute consultation with Lee Doughton?

Yes, Schedule a callDynex DS2, Dynex DSX, Dynex Agility automated ELISA systems.

We are committed to helping your lab be more profitable by assisting in cost control.

Ask us about selling your used lab equipment.

Request a quote to see the total cost of ownership for your Dynex ELISA system in 90 minutes.

Dynex automation ELISA system

Why upgrade to an automated ELISA system?

Manual ELISA testing is labor intensive, time consuming, with results that are prone to human errors.

Upgrade to an automated ELISA system offers numerous advantages that significantly enhance your laboratory operations.

Reduced hands-on time

Automated systems like the DYNEX DS2, DYNEX DSX, and Dynex Agility significantly reduce hands-on time by automating sample preparation, incubation, washing, and detection steps. This allows technicians to focus on other critical tasks.

Increased throughput

Automation enables the processing of a higher number of samples simultaneously, increasing overall lab productivity and enabling more tests to be run in less time.

Consistency

Automated systems ensure precise pipetting, consistent incubation times, and uniform washing, reducing variability and enhancing the reliability of results.

Minimize errors

Automation minimizes human errors, such as pipetting inaccuracies and timing mistakes, leading to more consistent and accurate data.

Real-time alerts

Features like real-time alerts for gross-pipetting errors and automated result calculations ensure high-quality outputs and reduce the need for repeat tests.

Traceability and verification

Automated systems offer built-in traceability and verification processes, ensuring compliance with regulatory standards and providing peace of mind.

Request a quote today to see how the Dynex automated ELISA system can transform your lab operations.

U.S.-manufactured Dynex automated ELISA Systems

Looking to upgrade to an automated ELISA testing system?

The Dynex line of ELISA processing systems stands out as a premier choice:

- Made in the USA for quality assurance

- ISO certified for your compliance requirements

- 3 models with different throughput rates to fit your lab capacity and budget

Ask us to include your total cost of ownership including your comprehensive service plan, reagents, and consumables for your Dynex system.

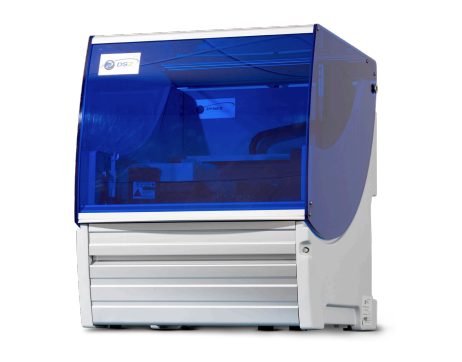

Compact Dynex DS2 automated ELISA system

Flexible Dynex DSX automated ELISA system

High volume DYNEX Agility automated ELISA system

Dynex DS2 compact automated ELISA system

Small footprint automation ELISA processor with low throughput

The DS2 system is perfect for smaller labs with limited space.

Despite its small footprint, the DS2 significantly enhances productivity and ensures fast and accurate results.

Dynex DXS offers flexibility to your ELISA testing process

Multi-tasking analyzer with medium throughput

The DSX system handles various assays and volumes simultaneously, delivering the speed and accuracy your lab demands.

Advanced automation features at every stage of the workflow provide the walk-away productivity that modern laboratories need.

Run multiple ELISA tests simultaneously on Dynex Agility

Run multiple ELISA tests simultaneously on Dynex Agility

High throughput workhorse for busy labs

Designed for high-volume processing, the Dynex Agility system lets you run multiple simultaneous ELISA tests with long walk-away time.

It reduces hands-on time by up to 60% and increases your current ELISA testing capacity.

If your lab needs to scale up your operation, this is the system to invest in.

Ask us to include your total cost of ownership including comprehensive service plans, reagents, and consumables for your Dynex system.

More lab profit with Dynex automated ELISA system

Automated ELISA processes reduce human error, improve result consistency, and increase throughput.

Your lab can also save significant consumable costs and optimize your human resources with the Dynex automation ELISA system.

Save on reagents

Optimize the use of reagents and consumables, so your lab saves on monthly expenses.

Reduced labor costs

Less manual intervention means your technicians are less likely to get operator burnouts. Instead, they can focus their energies on data analyses.

Future-proof your operations

Handle various assays and volumes, offering flexibility and scalability to meet changing lab demands.

Customizable solutions

Customizable platform to fit specific testing needs, ensuring they can adapt to new assays and workflows as required.

See your quote with the total cost of ownership including comprehensive service contracts, reagents, and consumables for your Dynex system.

Turn your old instruments into equipment budget!

Sell us your instruments and the cost of your Dynex ELISA system becomes even more manageable. We make equipment sales easy for you.

We give you a competitive value on your equipment based on set parameters

You get a clear payment timeframe and no hidden clauses

We assist with the decontamination plus we arrange

and pay for all shipping changes. Your process is hassle free.